Circular Design Metrics

Written by

Editorial TeamPublished on

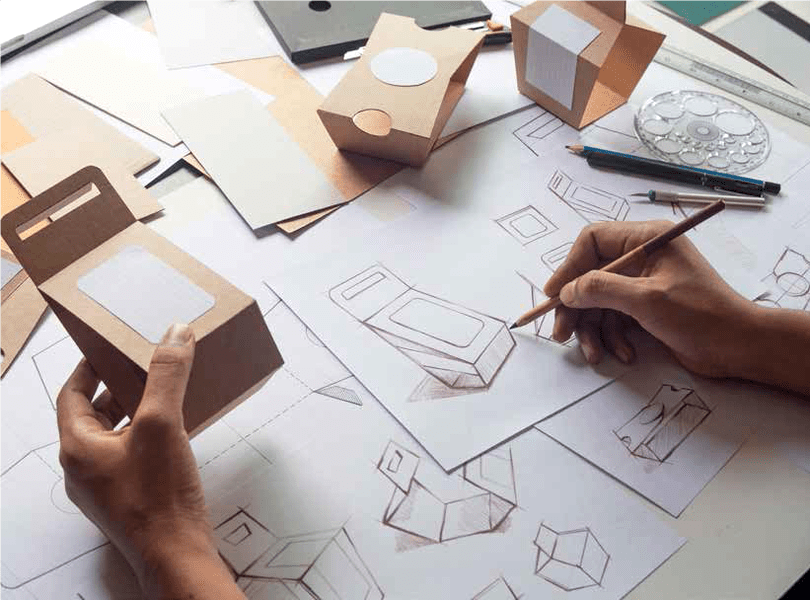

DS Smith has announced another milestone in its commitment to lead the way towards a more Circular Economy. The sustainable packaging giant unveiled its Circular Design Metrics, an industry first that allows customers to rate circularity of their packaging.

The pioneering initiative provides a unique insight into how companies packaging choices can reduce their impact on the environment. Through the collaborative design process customers will be able compare the environmental performance of different solutions to create more circular packaging.

Stefano Rossi, Packaging CEO at DS Smith, commented: “It has never been more important for companies to manage their impact on the environment. We want to show brands the beauty of the circular economy and allow them to explicitly understand what their packaging choices mean for that model. Our new Circular Design Metrics is a game changer in driving environmental performance in packaging. We’re excited to use our expertise to help companies, large and small, on their journey to become circular ready.”

The Circular Design Metrics is a new breakthrough tool that makes it possible to see and compare the performance of a packaging design across a range of indicators, such as recyclability, renewable content, supply chain optimization. The metrics include eight different indicators that provide a clear indication of circularity performance and help identify areas with potential for improvement. The tool is a first of its kind for brands that want to drive sustainability performance through their packaging.

DS Smith launched its Circular Design Principles for packaging in collaboration with the Ellen MacArthur Foundation in 2020. The Principles were developed to help companies design out waste and pollution, keep products and materials in use, and regenerate natural systems. Now, one year later, the company has trained its 700 packaging designers to apply the Circular Design Principles in the packaging design process. With the addition of the new Circular Design Metrics it will be possible to rate the impact of every design decision, and help customers create the most circular packaging solutions. DS Smith will embed the new metrics in the packaging design process with customers over the coming months.

Joe Iles, Circular Design Lead from the Ellen MacArthur Foundation, commented: “The design stage has a huge influence on how products including packaging are produced, used and what happens to them after use. DS Smith’s Circular Design Metrics are a key milestone to help drive change towards a circular economy. As a Strategic partner, DS Smith has the ability to make change happen faster by mobilizing its large design community and influencing its customers, many of which are global brands. And what’s more, the company will also inspire many other businesses and designers worldwide.”

Today’s announcement builds on the company’s ongoing commitment to put sustainability first, as it continues to develop innovative packaging solutions that ensure for 100% recyclability or reuse, optimising every fibre and offering alternatives to problem plastics.

5 Circular Design Principles

1. Protect brands and products: Packaging protects products, and all the resources invested in them from physical damage & waste (impact drop and vibration), environmental conditions (heat, moisture and dust) and protect people from harm (ergonomic and ease of handling).

2. Optimise materials & structure: Not using more material than necessary. Optimising the use of packaging materials saves resources and reduces waste, including physical construction (using material only when needed) and material direction.

3. Maintain & Recover Materials: The quality, durability and recyclability are key to keeping packaging products and materials in use for as long as possible, eliminating waste. This means maximizing the use of the fibres and recognising the value beyond the primary function (reusability, collapsibility, recyclability).

4. Maximise supply efficiencies: Packaging makes supply chains more efficient, from converter to consumer. With an end-to-end approach that considers every step of the way from storage and warehouse optimization (cost and carbon savings) to customer’s factories, packaging lines and optimization of ergonomics.

5. We find a better way: By living our values we challenge ourselves and our customers to develop more circular packaging solution.

There is also a video version of that: Circular Design Principles – DS Smith Packaging